Introduction

Embodied carbon—the carbon dioxide emissions associated with the production, transportation, and installation of building materials—accounts for a significant portion of a building’s overall environmental impact. As the real estate industry shifts towards more sustainable practices, reducing embodied carbon has become an essential priority. However, defining and measuring embodied carbon is complicated by inconsistent baselines and fragmented data, making it difficult to track progress effectively.

The concept of the “time value of carbon” highlights the urgency of addressing embodied carbon now, as immediate reductions can have a greater impact on mitigating climate change.

Through modular technology, there is potential to address this challenge by rethinking how buildings are designed and constructed to reduce and accurately track embodied carbon. However, as revealed in a recent study that Assembly OSM pursued in partnership with Atelier Ten, the construction industry still faces considerable hurdles in establishing reliable baselines and ensuring consistent data collection across the supply chain. Without reliable reference data, projects which accurately account for their impact are more than likely incurring penalties from a carbon accounting perspective. This creates strong incentives for projects and companies to avoid embodied carbon analyses lest they return unfavorable results premised on unreliable data.

The growing importance of embodied carbon

The construction industry has long been a major contributor to global greenhouse gas emissions, with the built environment responsible for nearly 40% of total global emissions. While much attention has been placed on reducing operational carbon—emissions generated from building use, such as heating, cooling, and electricity—there is increasing recognition of the need to address embodied carbon. Unlike operational carbon, which can be reduced over time through energy efficiency improvements, embodied carbon is locked into the building from the moment materials are produced and assembled. Because these emissions occur upfront, reducing them now has a more immediate effect on limiting global warming. This makes it an urgent focus, especially as cities aim to meet ambitious climate targets. Modular construction approaches aim to offer scalable solutions that minimize carbon emissions and introduce transparency throughout the construction process.

The Assembly approach to building is inherently productized, lending itself to deep supply chain investigation and Embodied Carbon tracking in a way conventional construction is not.

The problem of baselines in embodied carbon

One of the primary challenges the industry faces is the lack of reliable, standardized baselines for embodied carbon. Without a clear and consistent reference point, it becomes difficult to measure progress or make meaningful comparisons across projects. The range of baselines currently in use is wide, and many are not fully reflective of real-world conditions.

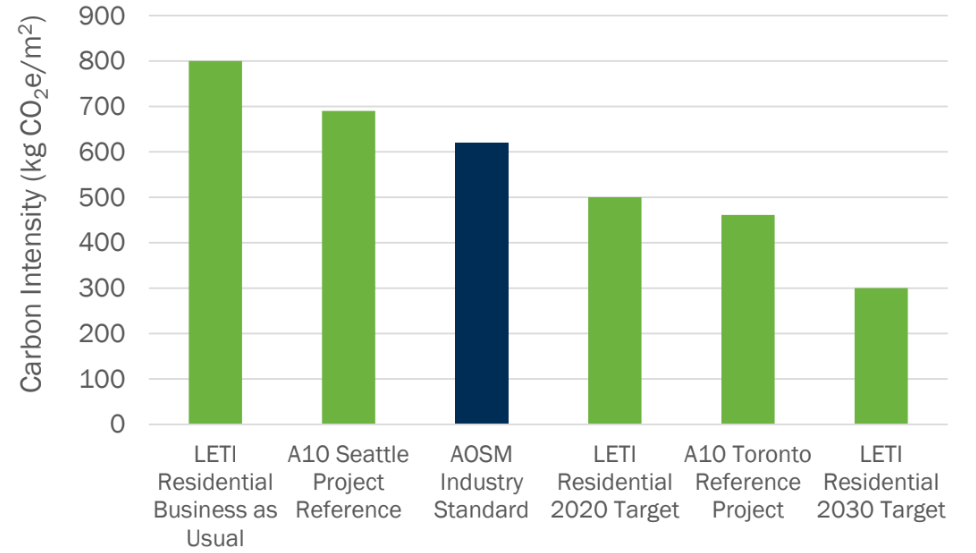

In our study, we used LETI (London Energy Transformation Initiative) references as a framework for benchmarking embodied carbon. While LETI is a well-respected resource for carbon reduction strategies, it presents certain limitations. LETI’s focus is largely on projects in England and Europe, which is not directly comparable to projects in the U.S. Additionally, LETI’s benchmarks are forward-looking, often based on aspirational goals for reducing embodied carbon rather than on actual results from real projects (LETI). While these targets are valuable for setting industry-wide goals, they do not reflect the current state of the market, where achieving such reductions may still be challenging.

Beyond LETI, the only other benchmarks available for our study were past projects for which Atelier Ten had conducted carbon analyses. This creates a self-selecting cohort of high-performance projects—those that were already committed to reducing embodied carbon and had the resources to hire consultants like Atelier Ten to conduct detailed carbon studies. As a result, the projects we benchmarked against represented the upper end of performance, which limits the comparability to more conventional projects.

The benchmarking of Assembly OSM’s Standard Product relies on very few comparable projects for comparison.

This wide range of baselines highlights a critical issue: how can we make meaningful progress in reducing embodied carbon if we do not have reliable, standardized data across a broad spectrum of projects? Without consistent benchmarks, it is difficult to know whether industry efforts are truly moving the needle.

Research by organizations like the Carbon Leadership Forum and the World Green Building Council highlights similar concerns, as well as active efforts to address this information gap. The Carbon Leadership Forum highlights the challenges of inconsistent baselines and the need for broader, comparable data across projects in their Problem Statement for v2 of the Embodied Carbon Benchmark Study: “it is difficult to set robust targets or benchmarks for the embodied carbon of building projects due to the lack of a robust collection of WBLCA models. Existing studies have been based on a very small number of calibrated models, or large low-quality and non-harmonized datasets, making it difficult to understand whether variability in carbon emissions stems from modeling practice, background LCI data, or actual design decisions” (CLF).

While this is a necessary stage in the development of any emerging dataset, it has the effect of undermining results, and thereby disincentivizing project teams from pursuing embodied carbon analyses. Similarly, the World Green Building council highlights the importance of “increasing market maturity to facilitate the development of common tools, databases and more standardized approaches including benchmarks, prescriptive design guidance and model policy toolkits… to support performance based assessments of materials, buildings and infrastructure” (WGB). These efforts are crucial as we hope to move the industry toward more reliable data and consistent baselines across global projects.

Additionally, multiple standards have debuted this year to help set targets and provide methodological guidance, including RICS, ASHRAE, UKGBC, and SBTi. Further, the ‘ECHO Framework’ was just launched, which is likely the largest effort – led by AEC nonprofits – aiming to standardize and harmonize the embodied carbon reporting process. The fact that there are so many competing frameworks demonstrates the crowded field and the need for a standard-bearer to emerge to give the industry a common language.

While the call to action and necessity of these changes is clear, the path to realizing change is less immediately evident. This is where GRESB plays a pivotal role in advancing sustainability within the real estate and infrastructure sectors, particularly by fostering transparency and data-driven decision-making. As the industry grapples with the challenge of reducing embodied carbon, GRESB’s standardized framework for reporting can significantly contribute to the development of more consistent and reliable data. By requiring participants to report on embodied carbon metrics across their portfolios, GRESB encourages a more uniform approach to data collection, helping to identify best practices and establish clearer benchmarks. This not only creates a competitive landscape where sustainability leaders are recognized, but also accelerates the adoption of strategies that lower embodied carbon across the industry.

Moreover, GRESB’s focus on improving ESG transparency can drive deeper collaboration between developers, designers, suppliers, and policymakers. The platform’s ability to aggregate and analyze data from a diverse range of projects provides valuable insights into current industry performance, highlighting gaps and opportunities for improvement. As more companies are incentivized to disclose their embodied carbon data through GRESB’s assessments, the collective industry knowledge grows. This will help refine baselines, enabling more accurate comparisons across regions and building types. Ultimately, GRESB’s work can serve as a catalyst for creating robust, widely accepted baselines that drive meaningful reductions in embodied carbon, pushing the entire industry toward a more sustainable future.

The role of supply chain data and accountability

The challenge of tracking embodied carbon extends beyond construction projects themselves—it runs throughout the entire supply chain. The embodied carbon of a building is not only a function of the materials used, but also of how those materials are produced, transported, and assembled. Ensuring accurate, reliable data requires transparency and accountability at every level of the supply chain.

Unfortunately, current supply chain practices often fall short in providing the necessary data to accurately measure embodied carbon. Many suppliers lack the systems or incentives to track their own carbon emissions comprehensively, leading to gaps in data or inconsistent reporting. This lack of transparency makes it difficult to assess the true carbon impact of materials used in construction.

Approaches such as that of Assembly’s, where there are high levels of supplier engagement to improve data collection and accountability, are crucial for accurately measuring embodied carbon. By collaborating closely with supply chain partners, it is possible to ensure that materials meet sustainability standards and associated carbon emissions are measured. This approach prioritizes the minimization of, and transparency around, embodied carbon at every stage of a project from design through occupancy. Through material innovation, offsite manufacturing and optimized logistics, greater visibility into embodied carbon can be achieved compared to conventional construction methods and their supply chains.

Conclusion

Innovative modular technologies, such as Assembly OSM’s, can minimize carbon emissions at every stage of the building process, an essential component of sustainable construction. However, the industry faces significant challenges in establishing reliable baselines and ensuring consistent data collection across the supply chain. This is where organizations like GRESB can catalyze real change by inducing a paradigm shift in market data collection.

Recognizing that immediate reductions in embodied carbon have a more substantial impact on mitigating climate change, the industry must act swiftly. By advancing the use of standardized data, improving supply chain transparency, and encouraging broader industry collaboration, we can continue to make meaningful progress in reducing embodied carbon. The future of sustainable urban development depends on it.

This article was written by Eddie Palka, Project Director and Andrew Staniforth, CEO at Assembly OSM.

References:

“CLF WBLCA Benchmark Study v2.” Carbon Leadership Forum. Accessed October 18, 2024.

“Bringing embodied carbon upfront.” World Green Building Council. Accessed October 18, 2024.

“Assembly OSM Whole Building Life Cycle Assessment.” Assembly OSM. Accessed October 18, 2024.

“Embodied Carbon Primer.” LETI. Accessed October 18, 2024.